Cast Acrylic Sheet

Adopting international famous brand Mitsubishi/Roma brand new MMA raw materials; light transmittance up to 92% or more, with excellent stiffness, strength and excellent chemical resistance; can be customized color, not easy to fade, non-toxic and tasteless, and can be up to food grade.

Adopting international famous brand Mitsubishi/Rome brand new MMA raw materials; light transmittance up to 92% or more, with excellent stiffness, strength and excellent chemical resistance; customizable colors, not easy to fade, non-toxic and tasteless, can reach the food grade.

Product Information:

Thickness: 1.5mm-50mm

Specification: common size 1220×1830mm, 1220*2440mm, 2050*3050mm

Other sizes can support customized size, please consult customer service.

Application industries:

(1) Advertising signs: signboards, display racks, advertising letters, signs, light boxes

(2) Construction industry: aquariums, windows, transparent roof, home lighting

(3) Furniture and sanitary ware: bathtubs, showers, acrylic coffee tables, tables and chairs, kitchen cabinets

(4) Rail transportation: sound barriers, separator screens, aircraft cockpit covers, windshields and glare windows

(5) Craft products: storage boxes, decorations, ornaments, photo frames, trophies, gift boxes

Product Characteristics:

(1) Good light transmittance

(2) High plasticity

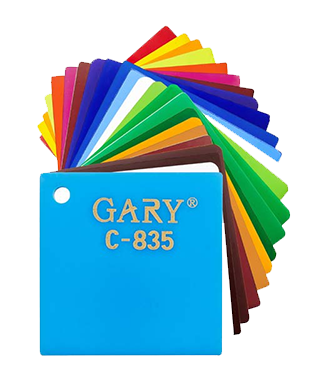

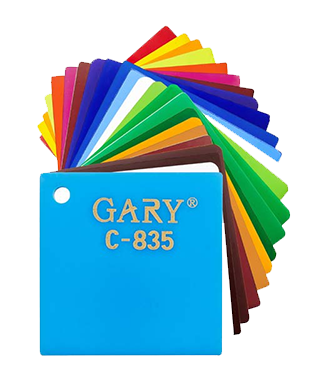

(3) Various colors

(4) Good weather resistance

(5) Long service life

(6) Light weight

(7) Strong impact resistance

According to the different production processes, acrylic sheet can be divided into:

Cast acrylic: high molecular weight, excellent stiffness, strength and excellent resistance to chemicals. This sheet is characterized by small batch processing, unmatched flexibility in the color system and surface texture effects, and a full range of product specifications for a variety of special applications.

Extruded acrylic: Compared to cast sheets, extruded sheets have a lower molecular weight and slightly weaker mechanical properties. However, this feature is conducive to bending and thermoforming processes, and facilitates rapid vacuum molding when dealing with larger sized sheets. At the same time, extruded boards have smaller thickness tolerances than cast boards. Since the extruded plate is a large-volume automated production, the color and specifications are inconvenient to adjust, so the diversity of product specifications is somewhat limited.

The difference between acrylic casting plate and acrylic extrusion plate.

1, casting plate in the transparency of 98% or more, while the extrusion plate is only 92% or more.

2, casting plate edge no pitting, and the edge is very transparent; extrusion plate edge will have pitting, and extrusion plate of the edge of the B class board can be seen yellow and black, extrusion plate of the edge of the A class board will be more translucent black.

Adopting international famous brand Mitsubishi/Roma brand new MMA raw materials; light transmittance up to 92% or more, with excellent stiffness, strength and excellent chemical resistance; can be customized color, not easy to fade, non-toxic and tasteless, and can be up to food grade.

Adopting international famous brand Mitsubishi/Rome brand new MMA raw materials; light transmittance up to 92% or more, with excellent stiffness, strength and excellent chemical resistance; customizable colors, not easy to fade, non-toxic and tasteless, can reach the food grade.

Product Information:

Thickness: 1.5mm-50mm

Specification: common size 1220×1830mm, 1220*2440mm, 2050*3050mm

Other sizes can support customized size, please consult customer service.

Application industries:

(1) Advertising signs: signboards, display racks, advertising letters, signs, light boxes

(2) Construction industry: aquariums, windows, transparent roof, home lighting

(3) Furniture and sanitary ware: bathtubs, showers, acrylic coffee tables, tables and chairs, kitchen cabinets

(4) Rail transportation: sound barriers, separator screens, aircraft cockpit covers, windshields and glare windows

(5) Craft products: storage boxes, decorations, ornaments, photo frames, trophies, gift boxes

Product Characteristics:

(1) Good light transmittance

(2) High plasticity

(3) Various colors

(4) Good weather resistance

(5) Long service life

(6) Light weight

(7) Strong impact resistance

According to the different production processes, acrylic sheet can be divided into:

Cast acrylic: high molecular weight, excellent stiffness, strength and excellent resistance to chemicals. This sheet is characterized by small batch processing, unmatched flexibility in the color system and surface texture effects, and a full range of product specifications for a variety of special applications.

Extruded acrylic: Compared to cast sheets, extruded sheets have a lower molecular weight and slightly weaker mechanical properties. However, this feature is conducive to bending and thermoforming processes, and facilitates rapid vacuum molding when dealing with larger sized sheets. At the same time, extruded boards have smaller thickness tolerances than cast boards. Since the extruded plate is a large-volume automated production, the color and specifications are inconvenient to adjust, so the diversity of product specifications is somewhat limited.

The difference between acrylic casting plate and acrylic extrusion plate.

1, casting plate in the transparency of 98% or more, while the extrusion plate is only 92% or more.

2, casting plate edge no pitting, and the edge is very transparent; extrusion plate edge will have pitting, and extrusion plate of the edge of the B class board can be seen yellow and black, extrusion plate of the edge of the A class board will be more translucent black.

Xishun

Chuangzhan(Shanghai) New Material Co,.LTD

Address:No.2 Factory Building, ,NO. 1501, Jiujing Road, Songjiang District, Shanghai, China

Email: info@xsacrylic.com

Tel/WhatsApp: +86-18321095766